The Energy Sector’s Digital Imperative

The Oil & Gas industry is transforming with LoRaWAN Oil and Gas Solutions driving digital innovation.

Facing the dual challenge of maximizing production efficiency while ensuring safety and sustainability, the sector is turning to Industrial IoT (IIoT) technologies. Among the most promising of these is LoRaWAN® (Long Range Wide Area Network) – a low-power, long-range, and secure wireless communication protocol designed for industrial environments

Key Industry Challenges

Oil & Gas companies operate in harsh, remote, and hazardous environments, where traditional wired solutions are costly, maintenance-intensive, or infeasible. The challenges include:

- Pipeline leaks and ruptures

- Unscheduled downtime due to equipment failure

- Inadequate visibility across remote assets

- Worker safety compliance in ATEX zones

- Rising OPEX and environmental risk exposure

These challenges are addressed by LoRaWAN Oil and Gas Solutions, with real-time data, wide coverage, and ultra-low power IoT connectivity.

OrbiWise, a global leader in LoRaWAN Network Server technology, offers a robust and scalable LoRaWAN network server – OrbiWAN – that enables Oil & Gas operators to build future-ready, sensor-driven operations across upstream, midstream, and downstream sectors.

Key Use Cases of LoRaWAN in Oil & Gas and Refineries

1. Pipeline Monitoring

- Leak detection (hydrocarbon or gas)

- Pressure, flow rate, and vibration analysis

- Corrosion and cathodic protection monitoring

- Tamper/intrusion alerts over long distances

2. Tank Farm & Refinery Automation

- Fuel, chemical, and water level monitoring

- Temperature and pressure tracking

- Valve position monitoring & automated alerts

- Overfill prevention and safety compliance

3. Predictive Maintenance

- Motor vibration monitoring

- Bearing temperature sensors

- Oil quality analysis

- Early fault detection with AI-ready data

4. Gas Leak & Hazard Detection

- CH₄, H₂S, CO₂, and VOC gas sensors

- Real-time alerts in explosive zones (Zone 0, 1)

- Automated shutdown integration

5. Worker Safety & Compliance

- Smart wearables for lone worker tracking

- Fall detection and panic alerts

- Heat exposure, toxic gas proximity warnings

- Zone entry-exit compliance records

6. Asset Tracking & Management

- GPS + LoRa-enabled trackers for high-value assets

- Utilization pattern analysis

- Theft or unauthorized movement alerts

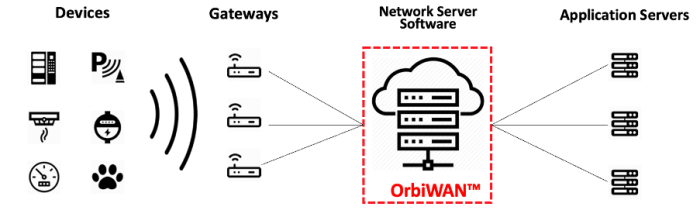

Technical Architecture: How It Works

- Sensor Layer: Battery-powered LoRaWAN ATEX-certified devices

- Gateway Layer: Rugged, outdoor gateways (cellular or satellite backhaul)

- LoRaWAN Network Server: OrbiWise’s OrbiWAN – cloud or on-prem deployment

- Application Layer: MQTT/HTTPS/Modbus integrations with existing SCADA, ERP, or cloud analytics platforms

Why OrbiWise? – The Network Server Behind Smart Oil & Gas Deployments

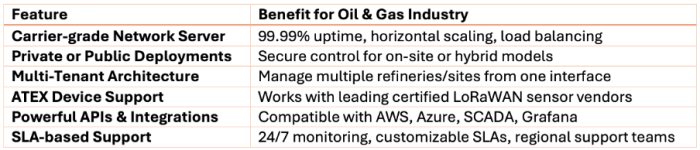

OrbiWise’s OrbiWAN is trusted by governments, telecom operators, smart city integrators, and industrial clients worldwide for its:

LoRaWAN Oil and Gas Solutions are transforming field operations with data-driven, safe, and efficient field operations. With OrbiWise’s OrbiWAN platform, your organization can take the next step toward a resilient and future-ready industrial IoT architecture.

Don’t wait for incidents to innovate. Start your LoRaWAN journey with OrbiWise – where wireless means business.

Ready to Digitize Your Oil & Gas Operations?

Whether you’re planning a pilot or a full-scale rollout, OrbiWise offers everything you need to get started:

- End-to-end LoRaWAN ecosystem expertise

- Pre-integrated sensor and gateway partners

- Flexible deployment options: public, private, hybrid

- Support in network design, planning, and SLA operations

- Global Offices: Switzerland | India | North America | LATAM | EMEA

Contact us today to discuss your use case, schedule a demo, or request a PoC setup.