Chevron is an acknowledged industry leader – constantly evolving and introducing new technologies in the energy industry

LoRaWAN IoT solutions offers new technologies to monitor and manage energy production operations in the upstream, midstream and downstream, leading to improved efficiencies, lower costs and waste and pollutant reduction or elimination that impacts the environment. There are countless technologies that make up the IoT, but Chevron has focused on several, including IoT industry leading LoRaWAN®.

Chevron chose LoRaWAN® Network Server over several other IoT technologies due to its superior features – long range, low power consumption enabling long-life battery life on devices and sensors, affordability and a large and growing ecosystem of network component suppliers. Chevron selected OrbiWise’s OrbiWANTM LoRaWAN® Network Server (LNS) to run it’s global networks after an exhaustive evaluation of all major LNS’ on the market. OrbiWANTM manages and provides oversight over all elements of Chevron’s LoRaWAN® Networks, including the devices, gateways, servers, and back-end applications and platforms.

LoRaWAN IoT Solutions Power Chevron’s Global Energy Network

With LoRaWAN® and OrbiWise, Chevron identified a technology and partner to enable IoT reach to all of its global operations. Using OrbiWANTM as the core to its LoRaWAN® Networks, Chevron has established networks on four continents in a little over one year of operation, with more to come. And within these continents, the network continues to expand from facility to facility to facility, indoor and outdoor.

These networks reach from cities to some of the most remote and rugged environments on the planet. Facilities utilizing LoRaWAN® range from remote oil & gas fields and platforms to refineries to staging areas to Chevron’s Headquarters in Houston, Texas.

How Chevron Uses LoRaWAN IoT Solutions for Operational Efficiency

What energy industry IoT applications is Chevron implementing to improve operations and environmental impact?

- Water metering and management – using only as much water as necessary and ensuring the water quality has no impact on environment.

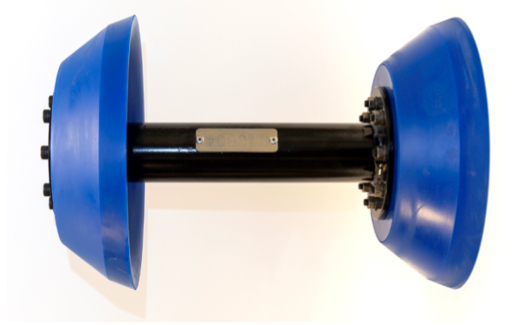

- Pipeline “pig” for general inspection, preventive maintenance, corrosion monitoring and cleaning.

- Valve monitoring and position management for operational efficiency.

- Steam temperature measurement and monitoring to optimize fracking operations.

- Asset and equipment tracking to prevent theft, loss and supply chain management.

- Fence and property boundary monitoring to ensure safety and environmental protection.

- Facility management and oversight to optimize work efficiency and safety.

There are many more industrial IoT solutions in development or under study – so stay tuned for future LoRaWAN® use case papers from Chevron and OrbiWise.

Fence & Property Boundary Monitoring

Pipeline Pig

Valve Position Management